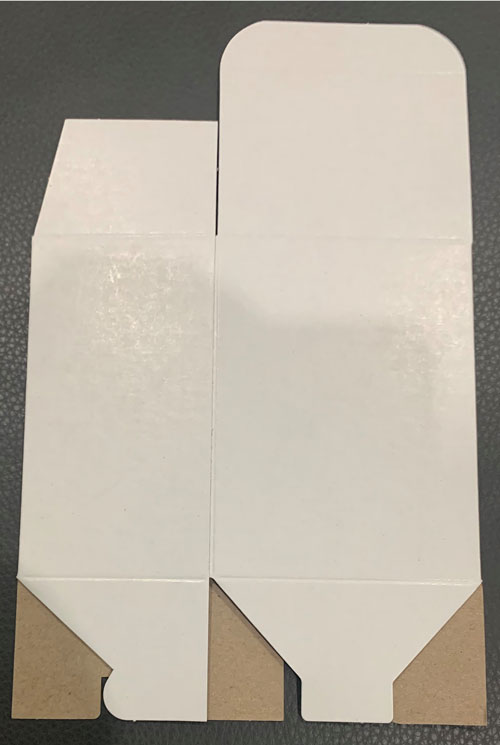

The 1-2-3 bottom is a type of packaging design used for cartons and boxes. It is often used in the seal food and beverage industry for products such as Blank boxes, takeout containers, and other types of food packaging.

The 1-2-3 bottom design is named for the way in which it is assembled. The bottom of the box is made up of three flaps, with one larger flap in the middle and two smaller flaps on the sides. These flaps are folded in a specific order to create a sturdy and secure base for the box.

This design has several advantages over other packaging designs. First, it provides a sturdy and secure base for the product inside, reducing the risk of damage during shipping and handling.

Second, the 1-2-3 bottom design is easy to assemble, with assembly easy to do for your product.

Finally, the 1-2-3 bottom design is visually appealing, with a clean and professional appearance that is suitable for a wide range of products and branding structure.

Overall, the 1-2-3 bottom design is a versatile and effective packaging solution that is well-suited for a wide range of Industries. Its sturdy base, ease of assembly, and professional appearance make it a popular choice for many different industries and products.

It’s really quite simple and fast. You don’t need to be an expert to use them either; they are relatively easy to assemble and can be done in less than a minute. It’s all thanks to their internal design that makes the assembly process quick and easy.